Cost and Power Savings With the New C&R Technologies

The new air conditioning and refrigeration technologies can achieve significant cost and power savings. The leaders of AEFYT, FEGECA, CNI and AFAR discuss how much they can cut bills in different cases.

Félix Sanz is assistant manager of AEFYT (Association of Refrigeration Companies & Technologies). He says that refrigeration technologies can be allies in achieving Spain’s environmental targets. “They’re vitally important for the user sectors that generate over 40% of Spain’s GDP, such as tourism and food.” Therefore, he adds that “in recent years, the cold sector value chain has constantly been making a big effort in R&D&I with special emphasis on making equipment more energy-efficient and achieving savings of over 30% compared to what was possible five years ago.”

To achieve this goal, businesses have been progressively switching to equipment that uses refrigerants with low or zero global warming potential (GWP) and optimum energy expenditure ratios. They have also been introducing disruptive technologies such as big data, artificial intelligence, virtual reality and blockchain. “They allow you to monitor the installation’s operation in real-time, to adapt the cooling to real needs at all times, and quickly identify and rectify any mismatch.

Electricity Bills

Javier Cano is an industry expert who works with AFAR (Association of Andalusian Refrigeration Manufacturers). He says that “with escalating electricity prices, energy saving is becoming more important again, once users have achieved their goals for greenhouse gas reductions and environmental requirements.” So, “new technologies help improve the energy efficiency of refrigeration and air conditioning systems with the consequent cost savings in electricity bills.”

He distinguishes between technologies specific to the refrigeration and air conditioning sector and other cross-cutting and Industry 4.0 technologies. “In the first type, one of the most important breakthroughs has been natural refrigerants such as R290 and ammonia which are clearly better than Freons in energy efficiency terms, with energy savings of up to 20%.”

Developing specific compressors and components for these refrigerants has resulted in a wide range of units and systems. “For example, low-charge ammonia technology in chiller plants is the most impressive implementation using natural refrigerants. Variable speed electronically commutated motors for compressors and fans are another good example of technological progress in components.”

On the other hand, various Industry 4.0 technologies applied to refrigeration allow for significant cost and energy savings. “Sensorisation and hyper-connectivity for equipment and systems, together with mass data storage and cloud computing, enable us to analyse an installation, to adjust its operating parameters properly, cut costs and start-up times, and achieve significant energy savings.”

Cano says that a well-adjusted cooling system can easily achieve 25% energy consumption savings. “At a later stage, an optimisation study of the installation can achieve further savings, through intelligent programming of equipment operation and by integrating cyber-physical algorithms.”

Finally, these digitalisation technologies also allow for predictive maintenance to ensure that the installation works in optimal conditions throughout its useful life. “For example, with predictive maintenance, we can predict problems with evaporator freezing in cold rooms, or reduced efficiency of compressors or pumps.”

Savings Of Up To 70%

Luis Nevares Moro is Vice President of the National Confederation of Installers (CNI). As a general rule, he says that savings will be similar for energy and cost as long as there are no major prices fluctuations. In addition, he says that “the present-day installation projects designed from scratch are completely different to those of thirty years ago. Technology has come a long way in terms of generation, control and isolation to avoid losses. We are talking about savings of 70% in buildings and even better for industrial processes. Just switching to latest-generation equipment using the same fuel, savings will be lower, but still considerable, as performance with the new equipment is around 30% higher.”

In his opinion, “the most useful improvement is to transform thermal installations to enable them to switch between fuels, or even in the energy mix. That way, you can switch to the most advantageous fuel as conditions change. Transforming existing inefficient installations is a unique opportunity for installers and users.”

That way, “a conventional installation that currently uses fossil fuel can be upgraded to use a more efficient technology, such as different classes of heat pumps, which are the most popular. That can achieve an energy consumption improvement of at least 50%, and if you add an electricity self-generation system that increases another 15%.”

Houses

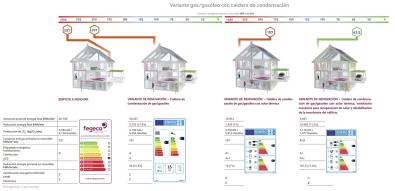

FEGECA (Association of Heat Generator and Emitter Manufacturers) presents an example of the modernisation of a 120 m2 family home in Burgos built in 1970. It demonstrates the energy savings that new air conditioning technologies can help to achieve. Its room heating and water heating installation consists of a 15 kW standard gas or oil boiler producing domestic hot water with a 200-litre inter-accumulator system. The example looks at three refitting options to achieve energy and cost savings in a house like this:

- Gas or oil condensing boiler: refitting with a gas or oil condensing boiler, a variable speed drive pump, domestic hot water from an inter-accumulator, thermostatic valves and heating regulated according to outdoor conditions (with external class 3 on/off sensor) and hydraulic balancing.

- Condensing gas or oil boiler with solar thermal: refitting with gas or oil condensing boiler, and heating regulated to suit outdoor conditions (modulating with external sensor and class 4 compensation curve), hydraulic balancing. Adding solar thermal energy for domestic hot water provides 60% of the demand defined in section HE4 of Spain’s Technical Building Code.

- Condensing gas or oil boiler with solar thermal, mechanical ventilation for heat recovery and refurbishment of the building envelope: refitting with gas or oil condensing boiler, and heating regulated to suit outdoor conditions (modulating with external sensor and class 4 compensation curve), hydraulic balancing. Adding solar thermal energy for domestic hot water to provide 60% of the demand defined in section HE4 of Spain’s Technical Building Code (CTE). With mechanical ventilation for heat recovery and flow rates defined in CTE section HS3. Refurbishment of the building envelope, including replacement windows with heat transfer coefficients recommended in the CTE section HE.